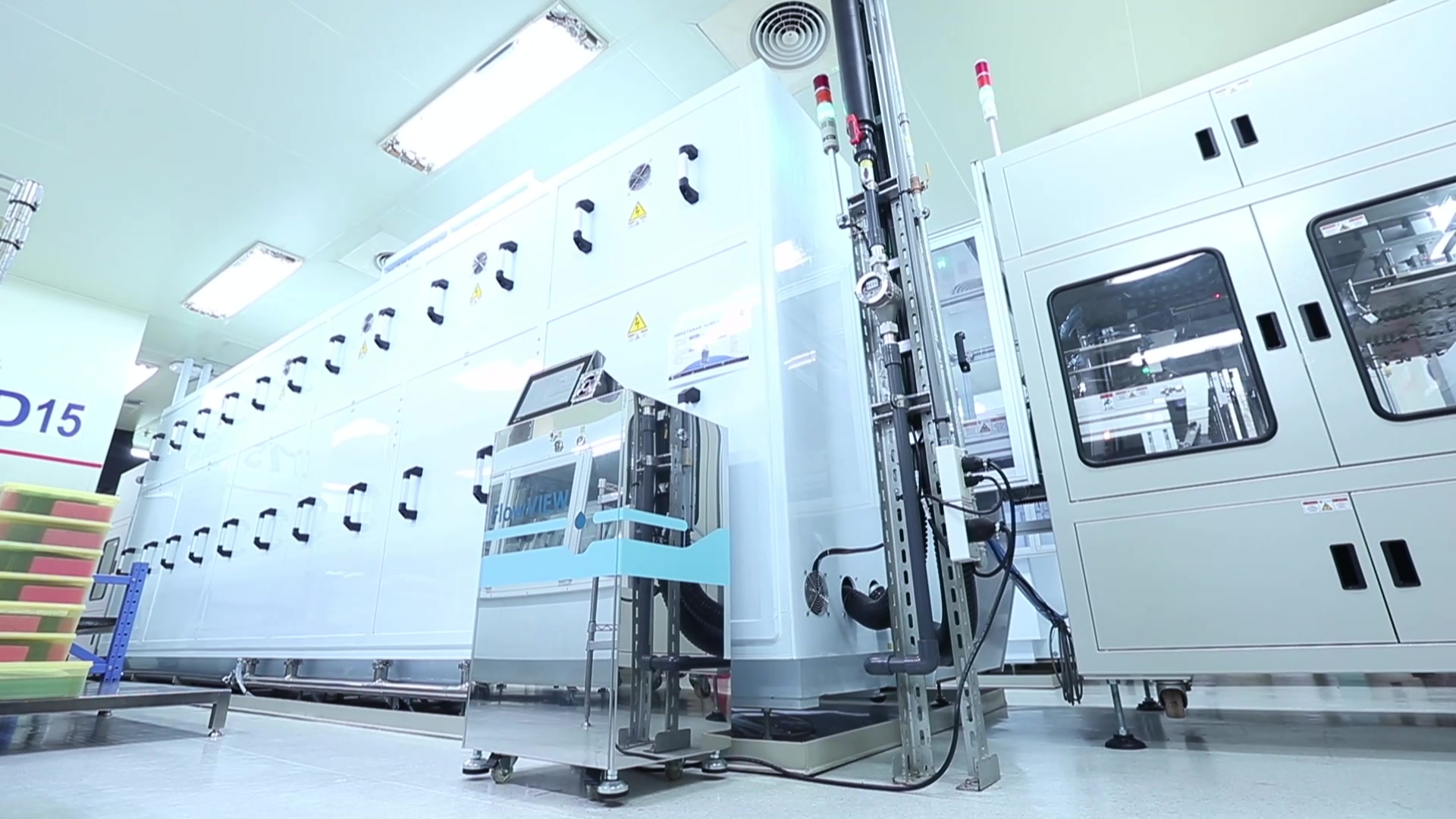

Inline Multi-Channel Liquid Particle Counter

Product Enquiry

Comprehensively grasp micronavid particle data and establish a complete production line operation history

Product Features:

- Direct integration into operating machines

- Automated multi-point analysis

- Monitor the number of micro and nanoparticles 24 hours a day

- Reduce ineffective movement and improve the efficiency of the cleaning process

- Cost savings of up to 72% per year can be achieved

- Developers, acid-mixed photoresist solutions, copper/aluminic acid, and DI water have good detection effects

Advantages:

Detect Predicition

Automatic warning, micro and nanoparticles appear micro-pollution conditions, cleanliness up to the warning standard, can be replaced in advance of the filter, to prevent the product condition

Optimize Recommendations

Intelligent cross-comparison of filter size, life, maintenance interval, and evaluation of process cleanliness. and provide optimization recommendations

Establish stable process standards

The cleanliness of the production line machine maintains a stable process standard to ensure that this process does not become a part of the customer's highlight

Semiconductor industry-wide applications:

Wafer Fabrication & Encapsulation Testing

| Product Advantages | Product Application | Import Customers |

|

|

|

Specifications:

| Measurement Range | 0.1 μm - 50 μm |

| Permissible Margin of Error | 40000 counts/ml @ 5% Coincidence Error |

| Correction | Traced back to NIST |

| Communication Mode | RS485/Modbus, 4~20 mA |

| Outer Box / Line / Sampling Interface | Non-grit Steel / PFA / quartz |

| LED Light Indication | Power/ Fault/ Normal Sampling/ Exception Warning |

| Sampling Temperature / Pressure | 0-70°C / 150 PSI |