ATOM Parts Cleaner

產品查詢

With the ATOM parts cleaner applying a unique dust capturing method with an adhesive gel sheet, an installation space for a dust collector or a dust is no longer needed. This gel sheet can be repeatedly used after cleaning off dust.

We provide A4 and A3 sizes on the assumption of cell production work. This allows efficient dust removal work to be done according to line design.

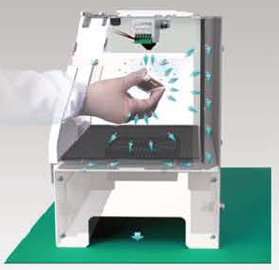

Static electricity elimination and dust removal in a hood. Dust adhered by static electricity is neutralized in the ionized hood and then removed by powerful automatic air blow.

ATOM parts cleaners playing an important role in line design of cell production. Assembled parts and devices can be cleaned on the spot and flowed to the next process, enabling line design to be smart.

Ionizing method : Piezoelectric high-frequency AC corona discharge. Applied voltage: 10kVAC (p-p)

- Compact bench-top type of 314 mm wide and 253 mm deep

- Eliminates static electricity and removes dust with air controlled by an infrared sensor.

- Time to stop ion blow after sensing a workpiece by a sensor is settable. (1, 3, 5, 10. or 30 sec)

- Adhesive gel collects blown-off dust assuredly.

- Dust on the adhesive gel mat can be washed off with water and the gel mat can be used repeatedly.

- Dust collector is not required; This reduces power consumption significantly and, in the end, the total running cost. Moreover, pulse blow also cuts the amount of air usage.

- In the pulse mode, air is blown intermittently, exerting force of blowing off dust by vibration. It allows low- and high-speed pulses to be selected according to workpiece.

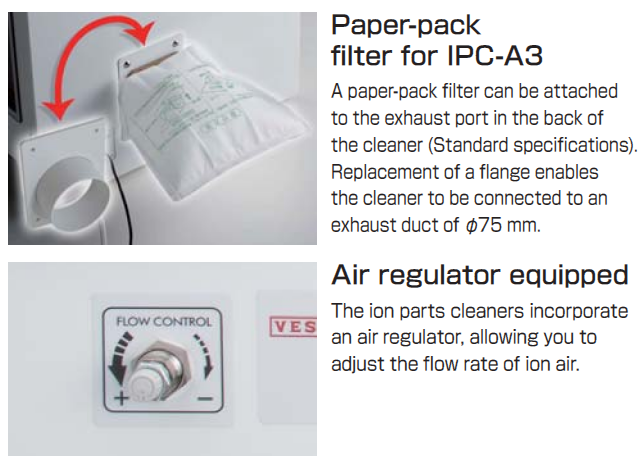

- Incorporates an air regulator.

RoHS

| Model No. | Power supply | Power consumption (W) |

Current consumption (mA) |

Dust collection airflow (m2/min) |

Airflow (ℓ /min) | Weight (kg) | EDP No. |

| APC-A4 | 24VDC±5% | 17 | 700 | 3.5 | 150 | 6 | 621610 |

(Noize: 0.3MPa Airflow: 0.3MPa)

Operating fluid: Clean dry air (0.1 to 0.5MPa), Air supply hose diameter Φ8㎜

Accessories: AC Adapter AD24-IT19E(100~240VAC), AC power cable 1.8m, Adhesive gel sheet/plate (attached on the product) (2pcs.)

Ionizing method: Piezoelectric high-frequency AC corona discharge. Applied voltage: 10kVAC (p-p)

- Equipped with two ionzing nozzles N-1, blowing air downward from the top side of the hood

- Eliminates static electricity and removes dust with air controlled by an infrared sensor.

- Time to stop ion blow after sensing a workpiece by a sensor is settable. (1, 3, 5, 10, or 30 sec)

- Adhesive gel collects blown-off dust assuredly.

- Dust on the adhesive gel mat can be washed off with water and the gel mat can be used repeatedly.

- Dust collector is not required; This reduces power consumption significantly and, in the end, the total running cost. Moreover, pulse blow also cuts the amount of air usage.

- In the pulse mode, air is blown intermittently, exerting force of blowing off dust by vibration. It allows low- and high-speed pulses to be selected according to workpiece.

- Incorporates an air regulator.

RoHS

| Model No. | Power supply | Power consumption (W) |

Current consumption (mA) |

Dust collection airflow (m2/min) |

Airflow (ℓ /min) | Weight (kg) | EDP No. |

| APC-A3 | 24VDC±5% | 22 | 900 | 1.13 | 190 | 9.5 | 621612 |

(Noize: 0.3MPa Airflow: 0.3MPa)

Operating fluid: Clean dry air (0.1 to 0.7MPa), Air supply hose diameter Φ10㎜

Accessories: AC Adapter AD24-IT19E(100~240VAC), AC power cable 1.8m, Adhesive gel sheet/plate (attached on the product) (2pcs.), Duct flange (For Ø75mm), Paper pack filter (6pcs.)

One point

Features of APC-A4 and -A3

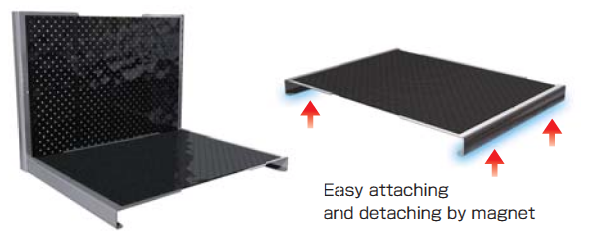

Dust capturing gel sheet for APC-A4 and -A3

Dust capturing using self-adhesive urethane gel. Adhesiveness is restored by cleaning such as washing in water.