Carbo e-Therm ACR70-200A.01

製品のお問い合わせ

Technical Data

Dispersion

based pm DIN EN ISO 2555, Spindle RV-04, speed 25 rpm

Dry coating

Application

Safety indications:

Application notes:

Disclaimer

All information concerning characteristics or applications of our product contained in this data sheet are given to the best of our knowledge and follow our latest technical developments.

Considering, however, the variety of possibilities and conditions of application, users of the product have to check if the product is suitable to serve their intended purposes.

We do not warrant any specific results. Users of our products have to observe applicable laws and regulations valid at their place. This data sheet is valid only in its latest version and

available on request at FutureCarbon GmbH.</class="product-spec"></class="product-spec">

Dispersion

| Dispersion base | |

| Specific resistance | 200 - 320 µΩ.m |

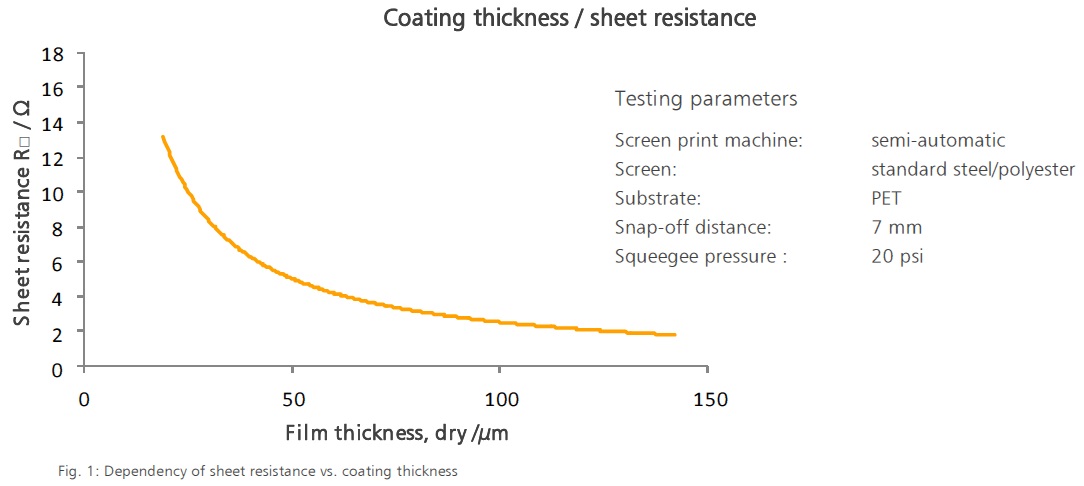

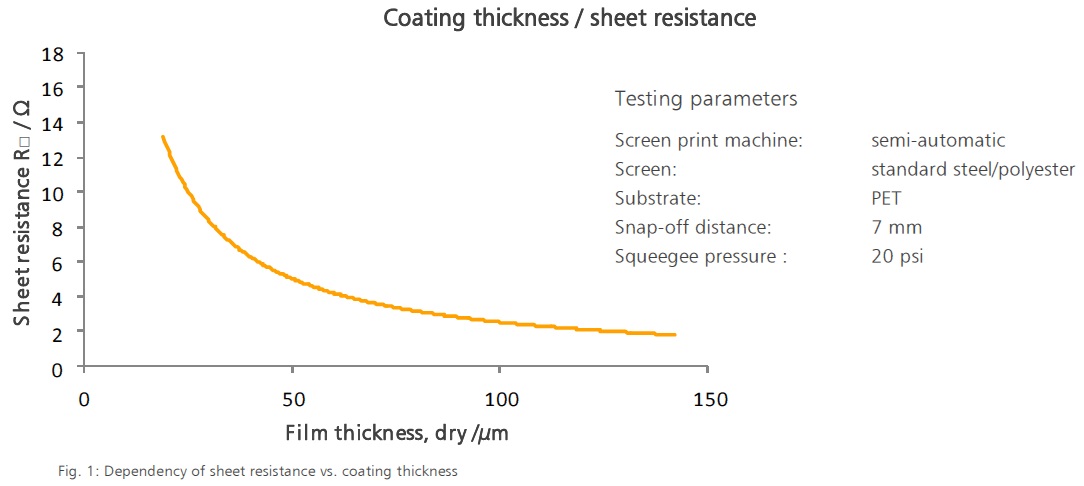

| Sheet resistance (R/square) vs. coating thickness |

16 Ω at 20 µm 5 Ω at 40 µm |

| Maximum particle size | 100 µm |

| Operating temperature | - 30 ºC to 70 ºC |

| Water resistivity | Hydrophobic dielectric layer is required |

based pm DIN EN ISO 2555, Spindle RV-04, speed 25 rpm

Dry coating

| Color | Anthracite |

| Specific resistance | 200 - 320 µΩ.m |

| Sheet resistance (R/square) vs. coating thickness |

16 Ω at 20 µm 5 Ω at 40 µm |

| Maximum particle size | 100 µm |

| Operating temperature | - 30 ºC to 70 ºC |

| Water resistivity | Hydrophobic dielectric layer is required |

Application

| Minimum layer thickness (wet / dry) |

75 µm / 20 µm |

| Coverage per coat | Up to 25 m2/kg |

| Dry time at 20 ºC | Dust dry: 25 min, Completely dry: 60 min |

Safety indications:

| Isolation & safety | The heated area is an electrical device, which is live when connected to a power supply. Therefore the coating needs to be covered with a dielectric layer for isolating against direct contact. Depending on the application a hydrophobic isolating coating is necessary. The national legal rules and regulations do apply. WARNING: Incorrect use together with electricity may cause fire hazard. |

| Storage | Keep out of reach of children. |

| Processing | During application do not eat, drink or smoke. Provide good ventilation while processing and drying. Do not breathe in sprayed product. Wash immediately with plenty of water after contact with eyes or skin. |

| Transport and disposal | See Material Safety Data Sheet (MSDS). |

Application notes:

| General Information | In addition to this document, users are strongly advised to refer to and follow all additional relevant documents (e.g. Material Safety Data Sheet (MSDS), instructions, etc.), which are available from FutureCarbon (www.future-carbon.de/contact/inquiry-form). |

| Field of application | Carbo e-Therm ACR70-200A is a heated coating used for heating applications with temperatures up to 70 ºC. |

| Substrate | Good adhesion on glass, FR4, wood and with Corona treatment on PVC, PMMA, PC and certain PET. Please contact FutureCarbon for further data. |

| Surface preparation | The surface should be dry, dust-free and free of any contamination that may interfere with adhesion. |

| Preparation | Prior to every coating application, thorough stirring of the dispersion with a suitable tool is required. Opened containers need to be sealed tightly and contents should be applied as quickly as possible. |

| Thinning | Dilution with water (up to 10% by weight) w/o change of specific resistance is possible. A thinner coating will be the consequence of thinning and should be considered for the design of the device. |

| Processing methods | Carbo e-Therm ACR70-200A was developed for screen printing. Further application methods are possible but shall be tested. Key is the realization of a homogeneous coating. |

| Dimensioning of heated application |

The dimensioning of the heating application in terms of heater geometry, coating thickness, heating power and power supply are mandatory for the system design. Please refer to further documentation. |

| Electrical connection, power supply |

A connection of the coating to a power supply via electrodes is mandatory to deliver the energy for the heating. A variety of conductive materials can be used as electrodes, for example copper band. The national legal rules and regulations do apply. The electrode material needs to be selected accordingly. |

| Cleaning | Cleaning of machinery and equipment with warm water or a high pressure cleaner immediately after usage is recommended. |

Disclaimer

All information concerning characteristics or applications of our product contained in this data sheet are given to the best of our knowledge and follow our latest technical developments.

Considering, however, the variety of possibilities and conditions of application, users of the product have to check if the product is suitable to serve their intended purposes.

We do not warrant any specific results. Users of our products have to observe applicable laws and regulations valid at their place. This data sheet is valid only in its latest version and

available on request at FutureCarbon GmbH.</class="product-spec"></class="product-spec">