APC Clean

Product EnquiryATOM cleaning device to remove static electricity and dust of circuit boards, molded components, and during powdering work.

Features:

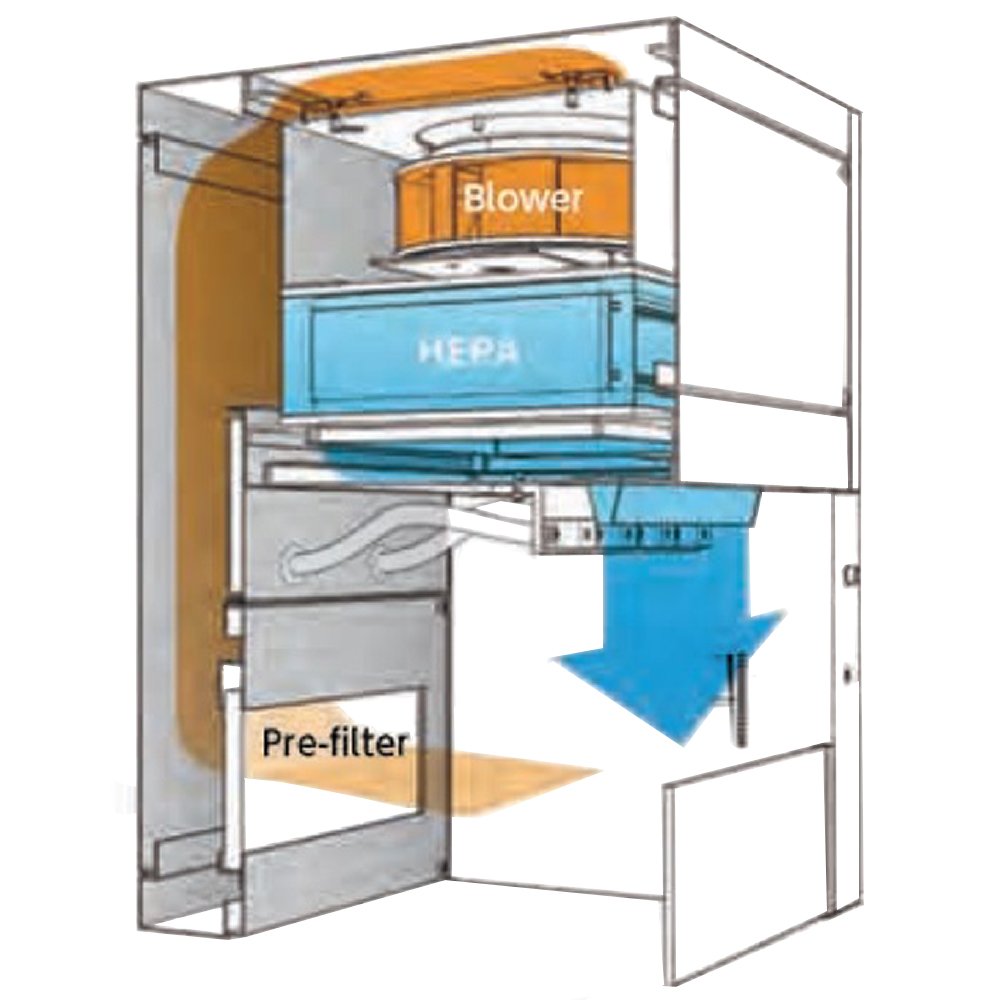

1. Clean blower air with HEPA filters

- Clean air with 99.97% of particles of 0.3µm retained by the filter. (Maximum: 25m/s of wind speed, 1.5m3/min of air flow)

- Acrylic resin plate, preventing diffusion of air in the front of the product. (Removable)

2. Installation of DC ionizer and creation of neutralization area

- A space 270W x 270D x 250H(mm) is ''uncharged".

- The ion balance can be adjusted and the needle electrode can be replaced.

- Warning lamp for high voltage error.

3. Air blow speed can be adjusted

- The amplitude of the wind speed is displayed by a 12-stage LED indicator. This is also a guide for replacing the HEPA filter.

- Minimize this will produce a nearly wind-free state, so it can be used for powder work that is not likely to splash

4. LED illumination

- Lightens your works brightly with LED lamps that can also be used as operating lamps.

5. Put the product on the wall surface

- No protrusions or power terminals installed on the back of the device. You can use the workbench space effectively.

6. Air circulation type, with no exhausted air

- The Air is vacuumed up from the pre-filter at the back of the booth passing through the inside blower and is filtered by the HEPA filter, then is blown back from the top of the booth.

Performance Data

- Static elimination performance/noise/wind speed

Measured on April 12. 2018 at 25ºC (temperature) and 45%RH (humidity).LED Level Decay Time Ion Balance

(±V)Noise

(dBA)Wind Speed

(m/s)Negative (sec.) Positive (sec.) 1 1.4 1.2 10 52.3 0 3 0.3 0.3 10 52.3 1.0 6 0.2 0.2 10 55 2.0 9 0.2 0.2 10 60 3.0 12 0.2 0.1 10 68 4.0 12(max.) 0.1 0.1 10 73.3 7.0

Decay time. Ion Balance measured with "TREK 158" CPM at 100mm distance from the air outlet.

Noise measured with "SL-1320" at 1m front.

Airflow velocity measured with "SK-93F" just below the air outlet.

- Air cleanliness (HEPA filters)<99.9% or more>

Measured on April 13, 2018Particle 0.3µm 0.5µm 5µm Total Primary Side 16,165,100 4,884,000 0 21,049,100 Secondary Side 420 0 0 420

Airflow: Max

Tested particle: PAO (Polyalphaolefin mist)

Particulate measured with KC-01DI (primary side, after air passing through the blower) and KC-03B (secondary side, after passing through the HEPA filter)

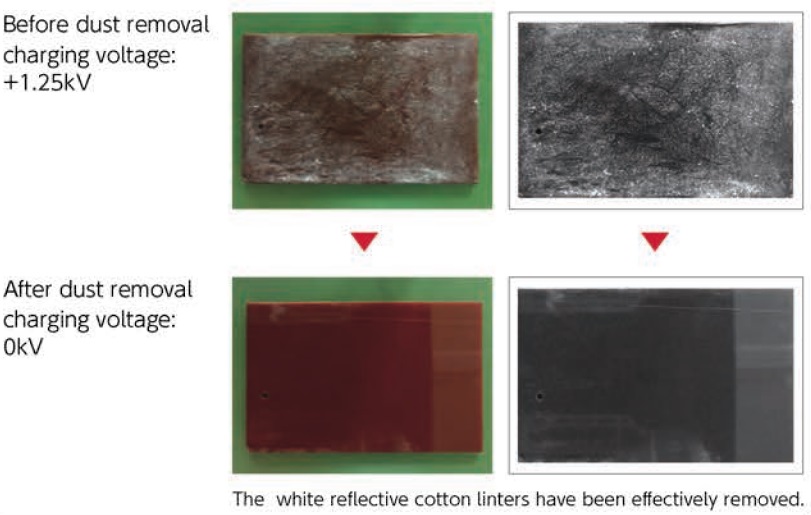

- Dust Removal Test

Sample: Bakelite plate (150 x 90 mm, 3 mm thick)

Pseudo-contaminant: cotton linter

Static elimination time: 3 seconds (inclined at 45° with respect to the air outlet)

Measured on April 11, 2018 with Electrostatic Field Meter Eye-02, at Max Wind Speed at 26ºC (temperature) and 45%RH {humidity)

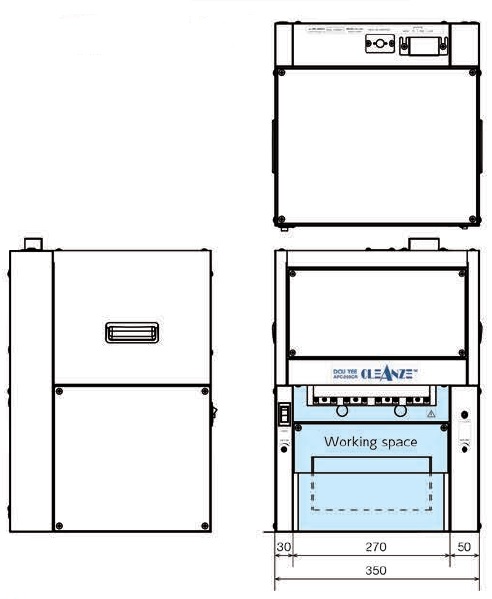

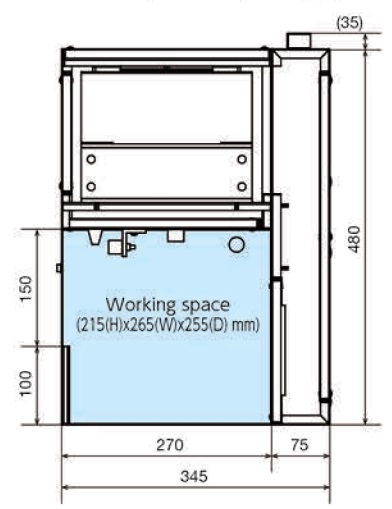

Dimensions

No. APC-250CR

EDP NO.623201

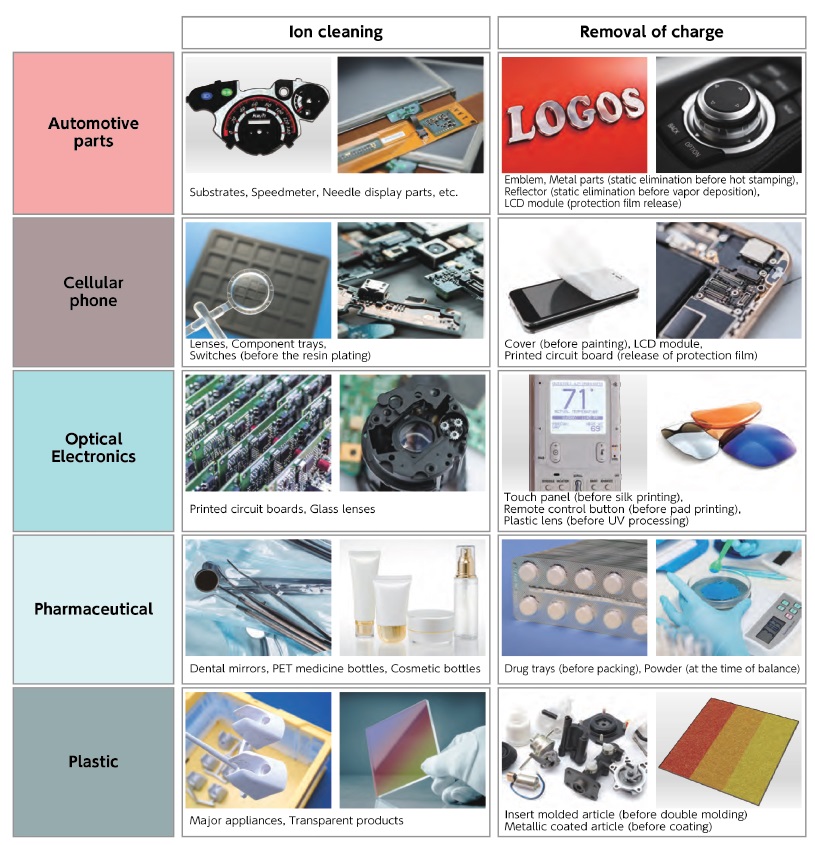

Applications (Static elimination and dust removal)

- For decomposition and repair of mobile phones and small electronic devices

- Before assembly of various receiving components

- Products before UV processing and silk printing

- Plastic moldings

- Glass substrates and semiconductor devices

- Before product packaging

unit: mm

Specifications

| Model No. | APC-250CR |

| Dust collection method | Built-in pre-filter and HEPA filter (two-stage) |

| Reference work size | A4 size with forward and backward changes, and A5 size without changes |

| Power supply | 24V DC ±5% |

| Power consumption | 108 W max. |

| Current consumption | 4.5 A max. (excluding inrush) |

| Protective function | Overcurrent protective fuses (250V 3A) |

| Air flow | Max. 1.5 m3/min (No internal filter clogging, output value of the blower) |

| Wind speed | Max. 25m/sec. (No clogging of built-in filter, output value of the blower) |

| Noise | 74 dBA (Maximum air flow, no clogging of built-in filter or deterioration of blower) |

| Operating temperature and humidity | +5 to 40ºC 35 to 65% RH (no condensation or freezing) |

| Size | 350W x 345D x 515H (without protrusions) |

| Weight | Approx.22 kg |

| Material | Steel Sheet (Munsell color N9.0. spray-painted finish) |

| Accessory | Caution label sticker / Instruction manual |

Ionizer

| Ionizing method | DC corona discharge type |

| Number of discharge electrodes | 4 pieces (Positive 2 and Negative 2) |

| Applied voltage | +6kV、-3 to -7kV |

| Effective static elimination current | 24V DC ±5% |

| Electrode coupling method | direct coupling |

| Material of the discharge electrode | Stainless-steel |

| Ion balance | ±30V |

| Decay time | Within 1 second measured at 100mm from the air outlet (±1000V ➜ 100V) |

| Alarm output | High-voltage output stop warning (red LED) |

Maintenance time *It depends on usage conditions.

| Pre-filter | 1 week (recommended daily cleaning) |

| HEPA filter | 1 year |

| Discharge needle | 1 week |

Application