CarboShield ACR450-PR.01

Product EnquiryCarboShield is a highly effective shielding wall paint for protection against electromagnetic radiation with up to 99.9 % effectiveness. This carbon based wall paint is applicable in homes & buildings.

Technical Data

Dispersion

| Solvent base | Water |

| Solids by weight | 54 - 55% |

| Mass density | 1.28 g/cm3 |

| Color | Anthracite |

| pH-VALUE | 7 - 8 |

| VOC content1 | < 0.2 g/l |

| Shelf-life (unopened) | 6 months |

| Storage conditions | Cool, but frost-free (>5ºC), avoid direct sunlight (max. peak < 35ºC) |

| Processing temperature | 15 ºC - 35 ºC |

| Labeling (GHS) | None |

| GIS-code | M-DF01 |

Coating (dry)

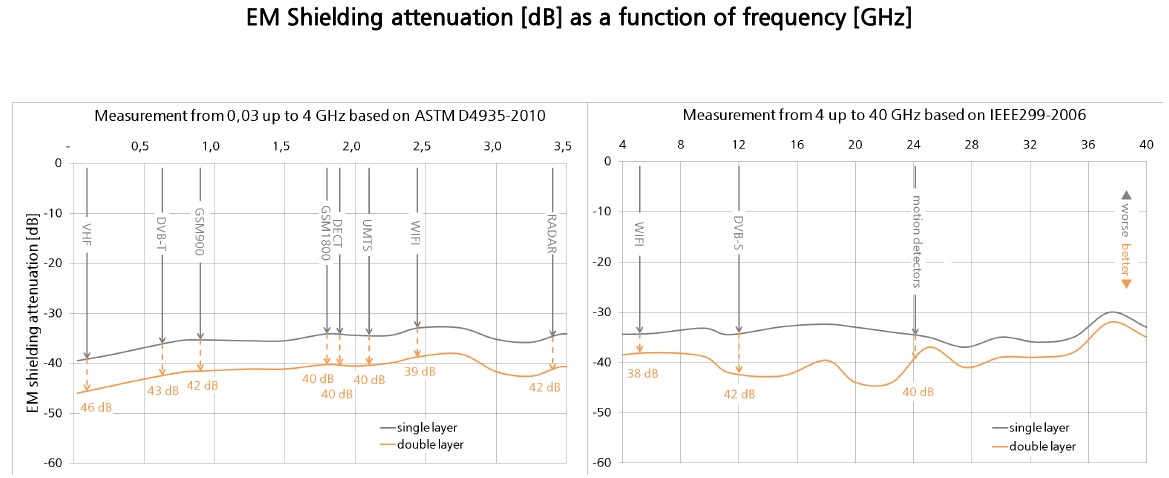

1 acc. to DIN EN ISO 11890-2| EM shielding attenuation (1 layer)2 |

Max. 40 dB |

| EM shielding attenuation (2 layer)2 | max. 46 dB |

| Sd value 3 (water vapor diffusion equivalent air layer) |

< 0.14 m (highly water vapor permeable) |

2 based on ASTM D – 4935-2010 as well as on IEEE299-2006

3 acc. to DIN EN ISO 7783:2012

Application notes:

| Field of application | Carbo Shield provides high efficiency protection against electromagnetic radiation for homes and buildings. |

| Coverage per coat | Depending on surface approx. 6 - 7 m2 per liter are achievable |

| Surface | Good adhesion on most common construction surfaces such as wall paint, plasterboard, wood or cork. |

| Surface preparation | The surface should be dry and free of loose material and any contamination that may interfere with adhesion. Absorbent surfaces should be treated with a base coat or primer. |

| Electrical grounding | An electrical earth grounding of the coating is mandatory. Usage of a copper tape is recommended. The earth ground connection of the copper tape needs to be installed by a professional electrician. |

| Preparation | Prior to every coating application thoroughly stirring of the dispersion with a suitable tool is required. Opened containers need to be sealed tightly and content shall be applied as quickly as possible. |

| Processing methods | Rolling: Apply evenly with a pile roller (ca. 5 – 8 mm pile). Spraying: Spray evenly with a spray gun with a spray valve not smaller than 1 mm. Smaller spray valves may be blocked. A 10 % dilution with demineralized water is recommended. |

| Dry time | At 20 °C and 65 % relative humidity coating is recoatable after approx. 50 minutes. With lower temperatures and higher humidity dry time increases. If several layers are applied, individual drying is necessary. |

| Overpaintability | CarboShield can be overpainted with aqueous indoor paints. It is recommended using a double layer top coat with well covering dispersion or dispersion silicate paint. |

| Thinning | Generally, a dilution (up to 15 %) with water is possible. However, change of screening effectiveness may occur then. |

| Cleaning | Cleaning of tools with warm water immediately after usage. |

Safety indications:

| Storage | Keep out of reach of children. |

| Processing | During application do not eat, drink or smoke. Provide good ventilation while processing and drying. Do not breathe in sprayed product. Wash immediately with plenty of water after contact with eyes or skin. |

| Disposal | Do not allow this material into drains, groundwater or soil. Only recycle completely emptied containers. Containers with liquid material residues should be disposed of via special waste collection services. Dried material residues can be disposed of together with domestic waste. |

| MSDS | Further details can be found on the material safety data sheet |

Disclaimer

All information concerning characteristics or applications of our product contained in this data sheet are given to the best of our knowledge and follow our latest technical

development. Considering, however, the variety of possibilities and conditions of application, users of the product have to check out, if the product is suitable to

serve their intended purposes. We do not warrant any specific results. Users of our products have to observe applicable laws and regulations valid at their place. This

data sheet is valid only in its latest version (see: www.future-carbon.de).