The µWire AeroBar utilizes MicroPulse technology applied to a corona wire system for optimal performance. MicroPulse technology reduces ion recombination at the corona wire, thus increasing product efficiency and performance.

The µWire Bar is optimized for its unique corona wire design which produces more ions than emitter points. The corona wire design also permits the bar to be placed closer to substrates, diminishing the recombination of ions and the resulting "striping effect".

Features:

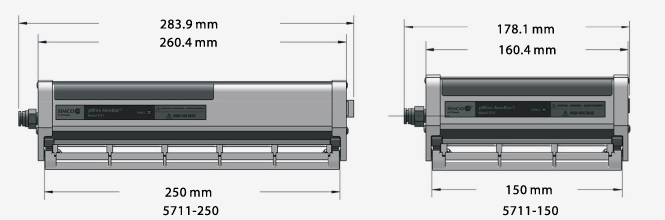

- Compact Size (150 or 250 mm length)

- Unique corona wire design (no emitter points)

- Micropulse high voltage technology

- Remotely mounted controller for 5711 AeroBar

Benefits:

- Charge protection for even the most space-limited automation tools

- Bar mounted close to target without ionization "striping"

- One swipe cleaning with bar in place

- Long-term balance stability and discharge time performance

- Uniform balance over the length of the bar

- Innovative ionization generation that translates to lower total cost of ownership

- Convenient access to power input, status lights and remote alarm connection

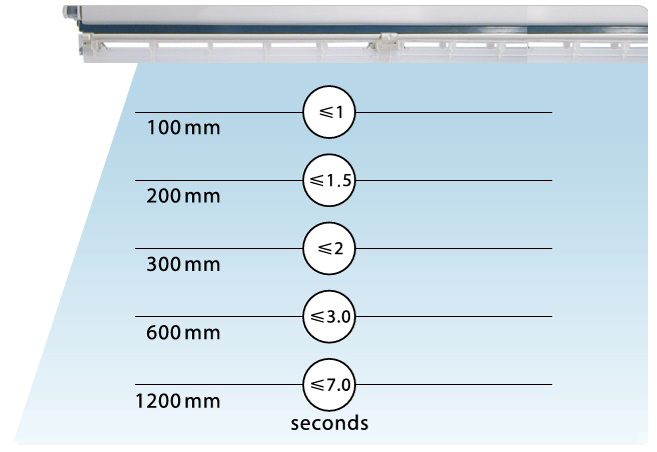

Typical Decay Time (sec)

µWire AeroBar Model 5711 (250 mm length) with 25 mm Air Jet Spacing. Measured using Simco-Ion CPM Model 280A with CDA flow at 2 lpm per air jet (18 lpm total) and no HEPA flow.

Specifications:

| 5711 | |

| Input Voltage | 24 VDC ± 10%, 12W max |

| Output Voltage | Adjustable 13kV pk-pk (typ) |

| Balance | <± 25V over the length of the bar |

| Working Range | 50- 2000 mm, application and specification dependent |

| Technology | Micropulse |

| Frequency | Factory default at 1 Hz, adjustable from 0.1 - 35 Hz |

| Cleanroom Class | ISO 14644-1 Class 2 |

| Controls | All parameters set via wired handheld terminal (HHT) by either wired connection or IR control to the 5711-CTRL Controller |

| Indicators | Power - Green; Communication -Yellow; Alarm - Red; LED combinations indicate specific status conditions |

| Gas Input | Clean dry air (CDA) |

| Gas Pressure | 3.45 bar (optimal); 6.2 bar max |

| Gas Consumption | 150 mm Aero Bar= 10 LPM, overall per bar 250 mm AeroBar = 18 LPM, overall per bar (Recommended flow is 2 LPM per jet orifice) |

| EMI Level | Below background level |

| Ozone | < 0.05 ppm |

| Operating Env. | 15 - 35°C, 30- 60% RH (non-condensing) |

| Enclosure | 5711 AeroBar: ABS Chassis; Stainless Steel Reference Plates 5711-CTRL Controller: Stainless Steel Chassis |

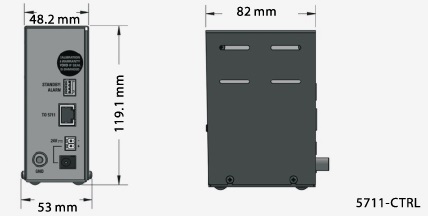

| Dimensions | 5711 AeroBar: 7.6H x 3.3W x Length (16 cm or 26 cm) 5711-CTRL Controller: 11.9H x 4.8W x 8.3D cm |

| Certifications |  |

Application Flexibility

The µWire AeroBar can be operated with the factory default settings in "plug-and-play" mode, or optimized for a specific application using the Handheld Terminal. The bar's ability to perform well in either a vertical or horizontal position along with the µWire AeroBar low profile height and length design makes it easy to install in a variety of flat-panel tool locations, conveyor and load/unload cassette areas as well as within many backend semiconductor assembly and test areas.

5711-CTRL Controller

The µWire AeroBar 5711 features a controller that can be placed in a convenient location for easy access to power input (local 24 VDC or power adapter from AC wall power), ionization status lights, handheld terminal setup connection and remote status connection.

Handheld Terminal

Emitter Wire Cleaner

The 5711 µWire AeroBar has a specific design emitter wire cleaner: placing foam swap inside the swap along the emitter wire, those accumulated dirts can be removed in a fast and simple way. The emitter cartridge can also be detached for replacement.