Simco-Ion's Point of Use Ionizing Blower Model 6432e controls static discharge in assembly, inspection, and packaging areas. The Model 6432e can also be used in-tool to control static build-up problems such as product contamination, material mis-handling or microprocessor lock-up.

lsoStat technology provides several useful benefits for the 6432e blower. It's small size and ability to operate in balance without grounding wires or cables allows easy and quick installation and setup. The blower's internal emitter points are electrostatically shielded to eliminate field-induced charging. Steady State DC operation provides fast discharge with low airflow for greater operator comfort.

Enhanced Features

An alarm LED on the front indicates a high voltage circuitry failure and a five-pin facility monitoring system (FMS) interface is on the rear of the blower, which provides a 4 - 20 mA current loop and relay output connection. With 24 VDC input connection, the FMS output is situated on a convenient terminal block, designed for easy integration.

Power Options

For increased flexibility, the Model 6432e Blower can be directly powered by process equipment or 24 VDC or 24 VAC power to fit the needs.

lsoStat technology provides several useful benefits for the 6432e blower. It's small size and ability to operate in balance without grounding wires or cables allows easy and quick installation and setup. The blower's internal emitter points are electrostatically shielded to eliminate field-induced charging. Steady State DC operation provides fast discharge with low airflow for greater operator comfort.

Features:

- lsoStat® technology

- Steady-state DC ion emission

- 24 VDC or 24 VAC input power

- Facility Monitoring System (FMS) interface

- Operational failure alarm

- Small footprint design with in-tool stand or benchtop stand

Benefits:

- Intrinsically balanced; no calibration needed

- Minimum ion recombination provides maximum static control

- Convenient power options, wall-provided AC or tool-provided DC

- Faster response to ionization failure

- Provides visual notification of failures

- Occupies little work or tool space, and cleanroom-compatible.

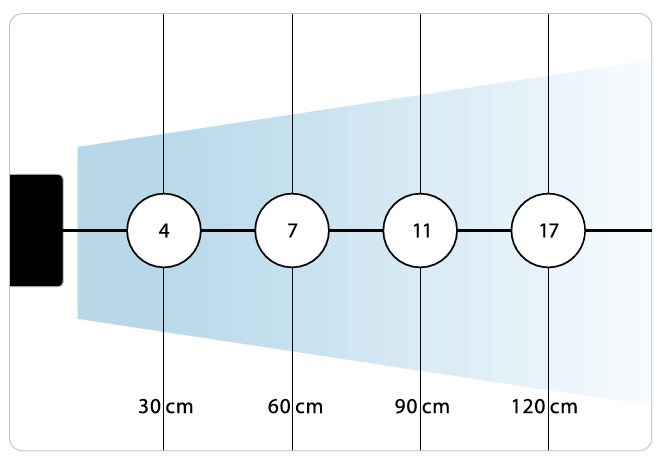

Typical Decay Time (sec)

Specifications:

| 6432e |

|

| Input Voltage | 24 VDC or 24 VAC, 50/60 Hz, 6 W max |

| Decay Time 1 | <4 s @ (1000 V to 100 V, 30cm, 24 VAC input |

| Balance | ± 20 V @ 30cm |

| Technology | Steady-state DC |

| Emitter | Tungsten; internally shielded |

| Cleanroom Class | ISO 14644-1 Class 5 |

| Indicators | Power - Green; Fault - Red alarm |

| Connections | Terminal block for power and FMS fault signal output |

| Airflow (m3/min) | 1.39 (typ) |

| Ozone | <0.005 ppm (typ) |

| Operating Env. | 10 - 35ºC, 20-60% RH (non-condensing) |

| Mounting | U-bracket : in-tool (4.5 x 12.9cm), benchtop (10.8 x 12.9cm) |

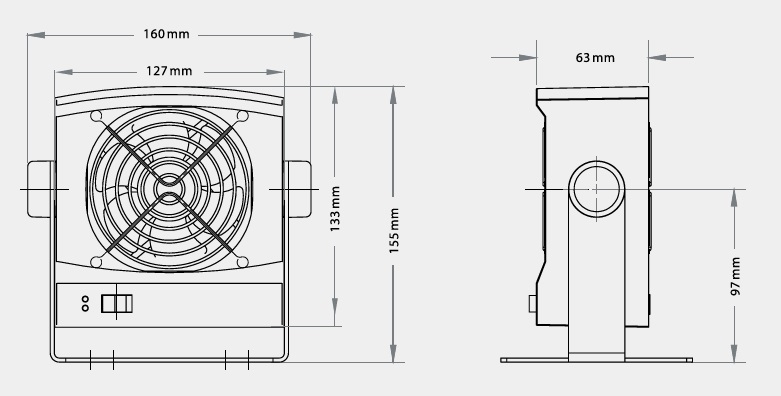

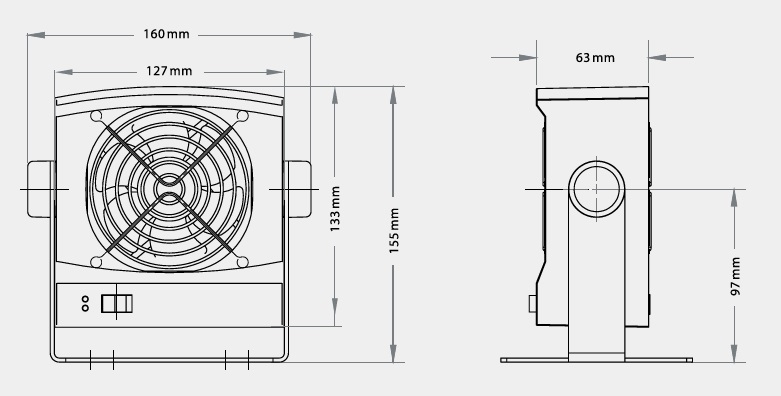

| Dimensions | 13.3H x 12.7W x 6.3D cm; Base (in-tool 4.5cm, benchtop 10.8cm) |

| Weight | With benchtop bracket 0.595 kg |

| Certifications |  |

Enhanced Features

An alarm LED on the front indicates a high voltage circuitry failure and a five-pin facility monitoring system (FMS) interface is on the rear of the blower, which provides a 4 - 20 mA current loop and relay output connection. With 24 VDC input connection, the FMS output is situated on a convenient terminal block, designed for easy integration.

Power Options

For increased flexibility, the Model 6432e Blower can be directly powered by process equipment or 24 VDC or 24 VAC power to fit the needs.